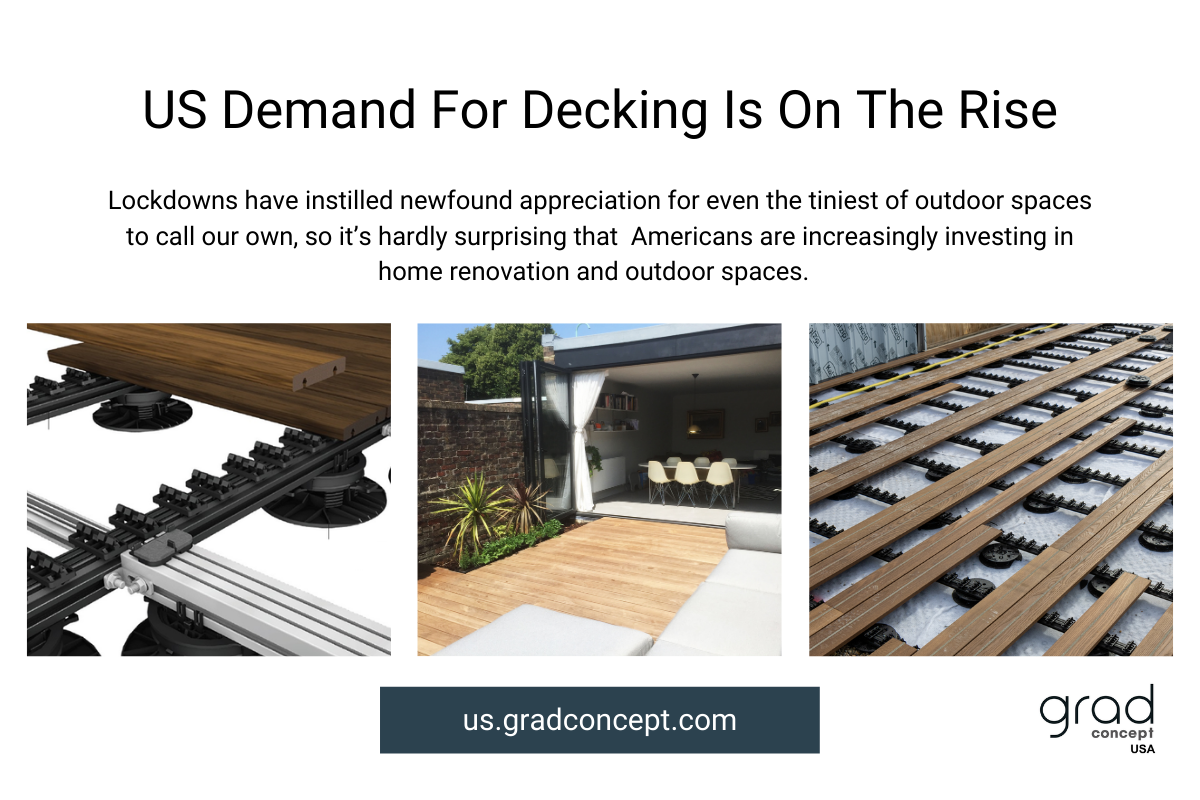

Lockdowns have instilled a newfound appreciation for even the tiniest of outdoor spaces to call our own, so it’s hardly surprising that Americans are increasingly investing in home renovation and outdoor spaces. As vacations and other plans continue to hang in limbo, the demand for decking solutions will continue to increase at an exponential rate.

Still, with the inventory at record lows, supply difficulties, and building material prices rising, the need to find reliable and cost-effective alternative solutions have never been so high in today’s construction market.

Builders and customers are looking for a world full of solutions with one well-designed product. They want ease, accessibility, and a design that they can trust to help them execute exciting and memorable projects.

The good news is, there are ways to save money when building your next deck; you just need to know-how.

Reduce operational costs and increase your productivity.

When opting to use Grad® you reduce your material costs, build your deck faster, and ultimately have to use less labor- costing you less money.

How?

Grad® comes as rails onto which clips are already pre-fixed. The rails can either be fixed on top of joists or used as joists combined with our own pedestal system. The clips are not your standard clips, they are specific to the Grad® system, and instead of gripping boards from the side, the clips get anchored into the boards to make a 100% hidden fastener deck. Since the clips are already fixed on the Grad rails, you are making a double saving: no clips to buy, no screws to buy = less material to buy, and up to 5x less time spent on the job. As an example, for a 200ft deck, you may need 0 screws and 0 clips.

It works like Lego.

How do the clips get anchored into the boards? You can use your standard boards, but only if they are grooved: the grooves will be the anchor points into which the clips will fit. You can either groove the boards yourself with a special set of router bits that we supply and that can simply be used on a CNC machine, or get pre-grooved boards from our US- or CA-based partners. The boards are simply snapped onto the clips: no need for extra tooling or extra care for this operation. Simply walk over the boards so that they get snapped in. The system’s extra benefit is it allows boards to be removed individually, at any time, and can then be put back into place. It is a fantastic feature that leaves the subdeck accessible at any time and is especially perfectly adapted to rooftop applications.

Faster, better, more robust finished product, giving you greater savings

With the clips already in place, installing your deck will be 5x faster because you will not need to screw clips individually, or measure gaps, or checkboard alignments either so you can move onto your next project quickly. Grad® takes care of it all because the clips are positioned exactly where the boards need to be. The easy concept will help you create perfect and safe decks within no time.

Want to know more? Get in touch.

*For more information, see Wood & Competitive Decking from The Freedonia Group.