If you are reading this post it’s fairly obvious that you have some level of commitment to creating higher-performing, better built and safer Outdoor Living structures. That’s inherent to the DNA of NADRA and the collective membership we’re humbled to be part of. We don’t just make building products and you don’t just make decks, we make the possibility of life’s memories, possible.

It’s time we expand our scope of better to include structural framing and drive the conversation of alternative framing methodology and products further from niche to normalized. There are incredible products available that outperform traditional wood – your customers deserve better and frankly, so does your artistry.

THE REALITY — MORE THAN HALF OF OUTDOOR STRUCTURES ARE UNSAFE

Here’s the truth: more than 50% of outdoor structures in the U.S. have past their safe service life — risking failure, injury and worse. The data isn’t new. yet we continue to build the same way. People trust decks and docks as a place to create memories, to provide a haven for their loved ones and to serve as the backdrop for life’s most precious moments. How many of these moments are being made with structural failure imminent and worse, they have no idea as they placed their trust in the capable hands of our industry? That’s why those who dare to build better must lead the charge — because safety isn’t a feature or a differentiator, it’s a standard.

While we celebrate and observe Deck Safety Month together, please join us in doing something bigger, starting with Deck Safety Summer and while we’re at it, Deck Safety Year. This is our call to action as an industry. It’s about educating ourselves, understanding the common failure points and choosing to do better.

THE FAIL POINTS — WHAT’S GOING WRONG?

Understanding what causes decks to fail is the first step toward building safer structures. Most commonly things like:

- Weak, improperly flashed, rotting ledgers

- Warped or cracked stringers

- Rusted and corroded fasteners

- Splintering and splitting joists

We have solutions, we have options, we just need to choose them!

BUILDING BETTER STARTS WITH BETTER FRAMING, WHY OWENS CORNING LUMBER?

When we introduced our Structural Framing product over 2-years-ago, we did so with the intention to provide a viable, consistent and easy-to-use alternative to pressure treated lumber. An alternative that installed like the wood you use every day but free from the irritants and issues you combat every day. A 100% wood-free Composite solution, GLAS-POWERED® and reinforced with glass fiber and rigorously tested both in the performance lab and the jobsite. Made for water, rotproof and underground/ground-rated.

The material arrives ready to install — straight, uniform and pre-dried. No cracks, no warps, no waste. It’s easy to work with and more predictable. It’s also engineered to resist cupping, warping and splintering while maintaining its integrity over time, even in the toughest conditions.

TWO EASY WAYS TO BE LEADER THIS DECK SAFETY SUMMER

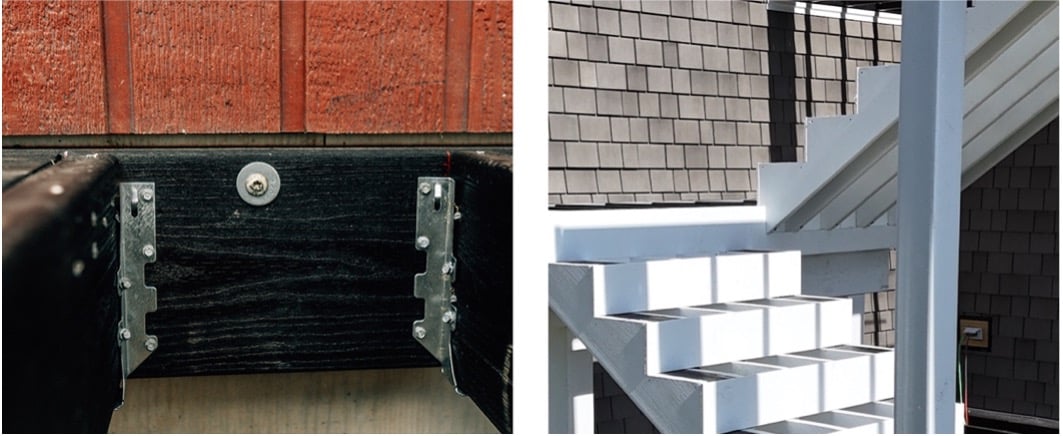

- Convert all of your Ledger Boards to Owens Corning Lumber

The most important structural component of your project deserves the highest performing material.

Using Owens Corning Lumber for your ledgers mean:

- Better resistance to rot and decay

- Stronger, more reliable connections

- Reduced risk of structural failure over time

- Build your Stair Stringers from Owens Corning Lumber

We designed our 2×12’s to offer next-level performance. Stringers bear the weight of people using the stairs and transfer that load to the foundation and support structure. Rotted, warped or cracked wood stringers compromise structural integrity and safety.

Building them out of Owens Corning Lumber:

- Allows stairs to sit directly on ground or in water without fear of decay

- Ensures durability and stability

- Extends the lifespan of your entire structure

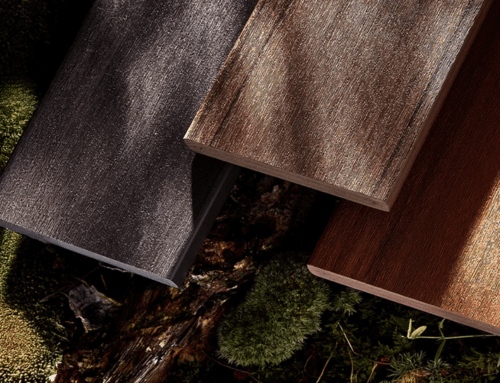

Remember: Owens Corning Lumber’s Structural Framing features a two-sided woodgrain finish in a range of colors meaning it’s not only a safer choice, it’s faster to install and can be less expensive than PTL, fascia and required fasteners.

Figure 1: Ledger board installed on left, a set of stair stringers on right. Both made from Owens Corning Lumber Structural Framing

STANDING TALL WITH LEADERS OF OUR INDUSTRY

Building better isn’t about compliance — it’s about leadership. It’s about setting a bigger example for ourselves and pacing our industry. It’s doing the right thing, because it’s the right thing to do and making safety, resilience, and craftsmanship non-negotiable.

“It all changed when we started thinking differently about the cost of alternative framing because if we are buying a $130 dollar deck board, our railing is $90 a linear foot, and our fasteners are a dollar a piece then it doesn’t make sense to put all this down on a joist that will rot in 10 years” – [Kevin Choquette, Ravin Builders]

“For our clients, Owens Corning Lumber Structural Framing injects long term value into our projects by significantly increasing the effective life of our exterior structures” – [Jermey Wilkins , Deck Van Gogh]

Let’s make deck safety more than a month, let’s make it matter everyday. Educate yourself on the new materials available – be in Owens Corning Lumber or the other great alternative framing solutions on the market.But don’t stop at materials. Equip your team in a bigger way. Use the tools, education and resources NADRA has created for us – become a Certified Deck Inspector!

When you build better, you’re not just elevating your craft, you’re redefining what’s possible.